Solución toop le TPTO Chelsea

le Chelsea P.T.O. Táan meenta'an yéetel betabi' utia'al u satisfacer le demandas robustas ti' le industria nu'ukulo'ob móviles. Continúe xookik tia'al a'alajil t'aan yo'osal diagnósticos utia'al u kajtalo'ob ichil u solución toop TTO. Wa k'áabet asistencia adicional, t'anik k ti' le 877-776-4600 o 407-872-1901, utia'al u tsikbal yéetel juntúul experto ti' le PTO Chelsea.

Tech u yil le ba'ala' A'alajil t'aan ti' solución toop u TTO ti' formato PDF beetik clic waye'.

Bey xan u yil k selección ti' Nu'ukulo'ob u páajtal a Chelsea PTO xíinbal k linki abas kaambal u nu'ukulo'ob.

Le P.T.O. Chelsea táan diseñados ka construidos utia'al u coincidan yéetel u yaantal jump'éel vehículo. Le engranajes jump'éel P.T.O. k'iine' le ti' jump'éelili' kuchil-calidad u le engranajes yaantal. Le funcionamiento exitoso yaantal yo'osal le especificación yéetel u le instalación ti'alo'ob. Consulte Mantats' u náakake' u yaak'il ti' Aplicaciones yéetel Manual u Instalación u Chelsea ka' meyajnakech yéetel Chelsea P.T.O.s. Beet le ba'ala' evitará jump'éel P.T.O grave. Toop.

Advertencia!

Advertencia!

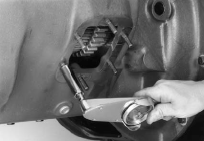

Solución toop u PTO ti' le vehículo:

Rendimiento

Le yáax kúuchil utia'al u kaxant le solucionar toop juntúul P.T.O. fallo táan kajnáalo'ob yo'olal.

Juntúul fallo repetido wa prematuro u páajtal u jump'éel signo jump'éel solicitud incorrecta.

Le je'ela' ku páajtal descubrir yo'osal u búukinta'al u

Catálogo aplicaciones HY25-3000 leti'e' EE. UU..

Wa u P.T.O. ku especificó belil ka ts'o'okole' falló prematuramente, Yaan ka'ap'éel tsa'ayal probables:

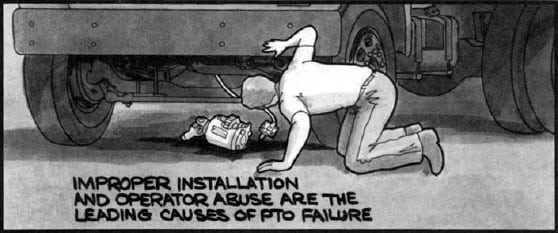

- Instalación incorrecta yo'osal u chíikpajal ba'ax búukinta'al u indebido le operador.

- Juntúul P.T.O instalado incorrectamente. normalmente je'el u páajtal u identificado inmediatamente tumen u juum (Juum) ku beetik u.

• U "Whine" ,"Clatter", "Click" wa "Grind"

• U Óoxten, le vehículo ti' yan u contribuir yéetel suficiente juum utia'al enmascarar u juum le P.T.O. yéetel juntúule' je'el ma' notar le talamilo'

Wa ku Cha' u jump'éel talamil continúe, tu p'ataji' ti' le P.T.O.. resultará.

Tipos u juum:

Establecer retroceso engranajes min. Utia'al .006 – .012.

- Quejar u – Jach apretado

- Juum – Jach suelto

- Meentik clic wa juuch'

Fugas – Causa moots le fuga

Roscas u stud

- Xanab u inadecuado le sujetadores

- Instalación incorrecta u Stud

- Instalación juntas

Focas

- Wa u yaantal yilik

- Sellos desgastados

Solución toop ti' le TP ti' yo'osal u meyaj:

Rendimiento – Taalamil & Tsa'ayal

P.T.O. Meyajo'ob – Yaan Hidráulico

- Meyajo'ob errática

- Chich k'eexpajal

- A puulkaba ichil paach Gear

Artículos u examinar ti' le banco meyaj

- Vivienda

- Engranajes

- Chumbesajil

- Rodamientos

- Cambiadores

- Embragues

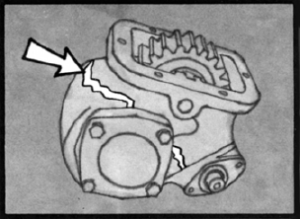

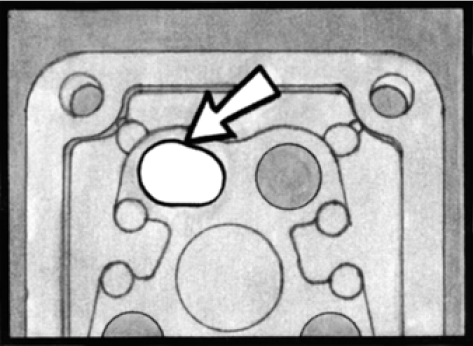

Tu p'ataji' ti' le vivienda

Juntúul le talamilo'ob asab graves ti' jump'éel P.T.O. Je'el u páajtal u muk'yaj le jump'éel óoltaj agrietado. Táan a u conducir le asab tsaats yéetel eventual falla yaantal.

Jayp'éel tsa'ayal le:

- Instalación incorrecta

- Pernos k'aas atornillados

- Bomba montaje beetaj ich u ma' compatible

- Meentiko'ob extraños mallando ichil kojo'ob le engranaje

- Kuuch choque grave

- Loxikaba'ex obstáculos ti' le bejo'

- Hilos dañados

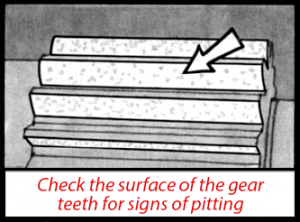

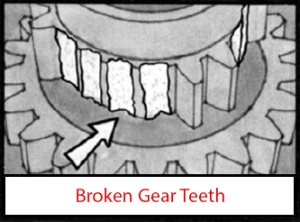

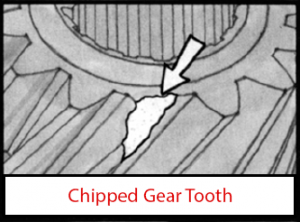

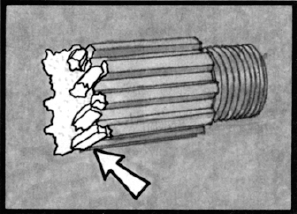

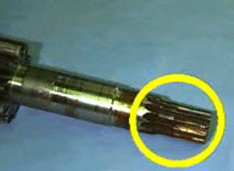

Tu p'ataji' ti' le engranaje

Le loob le engranaje le TTO ku tukultik a ti' koj wa u spline. Le primeras pak'chaje' u inspeccionar k'a'abéet u beel le engranajes. Compruebe le superficie kojo'ob le engranaje kaxt bix picadura. Una pakteche' ka u picadura le meyajo'ob le engranaje ts'o'ok u comenzado, Mina'an ba'al u páajtal u je'elel. Uláak' páajtal talamil ichil le funcionamiento u vehículo le u "kuuch choque". Patrón u malla taam causado tumen juntúul ajuste contragolpe incorrecto. Le engranajes desgastados ti' le TTO páajtal yiliko'ob u afectados uchik u "kuuch choque". Wa descuida reemplazar engranajes u usan, yéetel le páajtal conducir ti' u kojo'ob engranaje baakoobo'. Yaan k'iine' jump'éel engranaje astillará jump'éel koj debido a jump'éel k'aas ch'a'iko'ob wa k'eexpajal inadecuado. Le k'eexpajal inferior ku cha'antik le máax ku incompleto le koj le engranaje yéetel le engranaje le conductor. Lela' u k'áat u ya'al u chéen jump'éel nu'ukulil le anchura koj táan transmitiendo le xanab yéetel R.P.M. ti' P.T.O. Meyajo'ob.

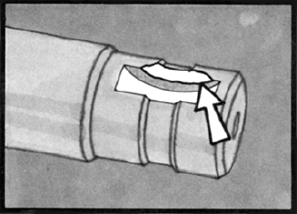

Loob ti' le bak'pach

P.T.O. chumbesajil xan ku vulnerables ti' le abuso operativo, sobrecarga torsional, fallo flexión le fatiga.

Ti' le inspeccionar jump'éel P.T.O. bak'pach salida, Mantats' inspeccionar le wach'ebo'.

Le loob ti' le bak'pach u TDF u ocurrir sobrecargas u yutsil meyáajtiko'ob incorrectas yéetel kuuch choque.

Le corrosión tumen nu'ukulo'obo' le uláak' bin yano'ob loob chumbesajil le le TDF páajtal a máansik. Ku chíikpajal bey jump'éel oxidación yéetel u desgaste le splines le bak'pach le bomba. Le corrosión tumen nu'ukulo'obo' causada tumen ya'ab ba'ax yéetel xma' le mantenimiento adecuado, le arrozo' anti-trastes chéen u xu'ulsiko'ob, Ba'ale' ma' tselik, u efecto yóok'ol le componentes.

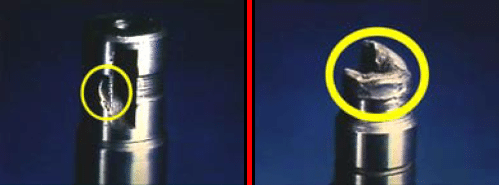

Toop k'eexpajal

Wa experimenta u u P.T.O. toop u k'ex, K'a'ajsik, jump'éel varillaje k'eexpajal accionado tumen palanca ma' k'a'ana'an conectar u ti' jump'éel cubierta k'eexpajal cable. Le ventaja kanáanil ti' le palanca nojoch in menudo jach utia'al u cubierta le k'eexpajal cable yéetel je'el dañar le gravemente. Xan inversamente, Ma' use jump'éel cable yéetel juntúul cubierta k'eexpajal palanca. The cable isn’t capable of transmitting the force necessary to shift a lever mechanism.

Most shifting complaints are caused by improper shifting procedure or incorrect linkage installation.

Shifting problems can also be caused by a worn or elongated shifter poppet hole.

Seals and O-Rings may cause special problems in P.T.O. operations.

Remember, when troubleshooting any clutch-operated P.T.O., carefully inspect all components for wear or damage. Burnt clutch plates, welded clutch pack, or a burnt driving hub are three easily identifiable conditions that lend themselves to failure analysis.

Juntúul señal segura posibles toop yéetel juntúul P.T.O operado tumen embrague. Leti' jump'éel operación errática.

le 3 quejas asab náats'al:

Juum

Tin wu'uyaj atentamente jump'éel lloriqueo wa jump'éel juum agudo. Le ba'ala' je'el u indicar toop yéetel le engranajes jach aniko'on, rodamientos wa sistemas hidráulicos. Jump'éel sonajero je'el u indicar toop yéetel le engranajes jach sueltos wa vibraciones torsionales.

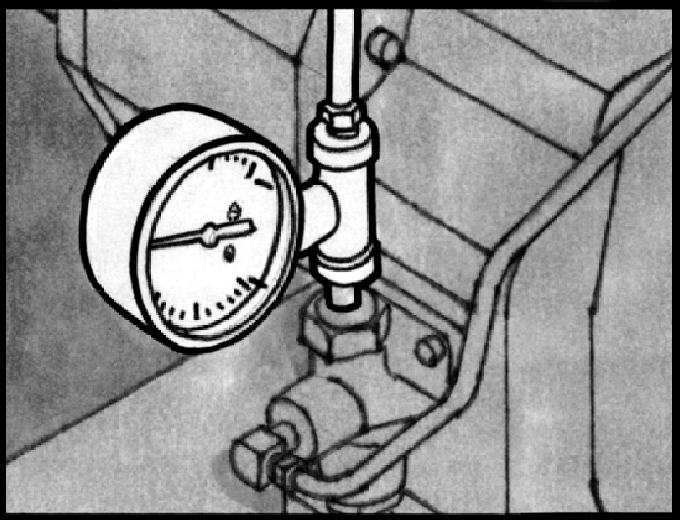

Toop molay

Le talamilo'ob enganche le TTO k'eexpajal potencia k'a'ana'antal deber u u mangueras wa accesorios bloqueados, k'aak'as conexiones wa lu'um wa le solenoide. Le talamilo'ob mecánicos u enganche le TTO k'a'ana'antal originar u ichil baja presión iik', instalación u cable inadecuada wa máatsabo'ob traseras u jach apretadas.

Toop separación

A máansik toop desconexión yéetel le TTO k'eexpajal potencia je'el indicar toop yéetel mangueras wa accesorios bloqueados, paquete embrague congelado wa le solenoide.

Prevención

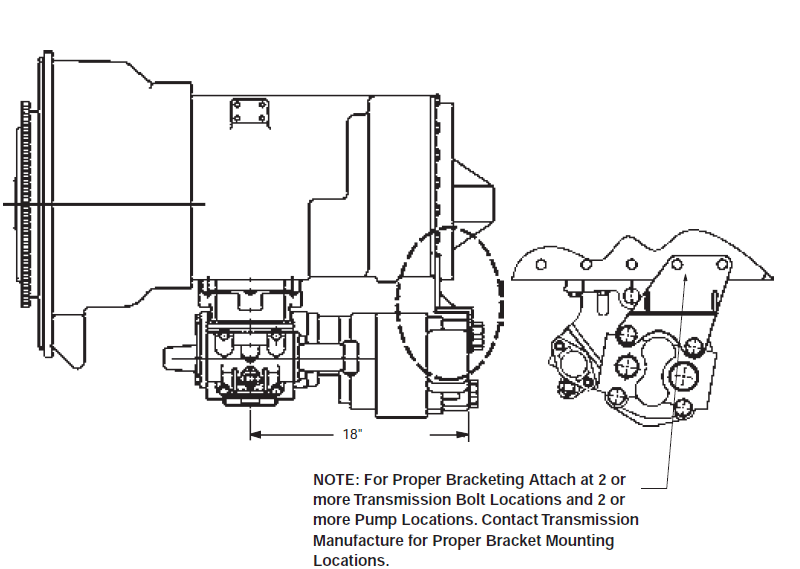

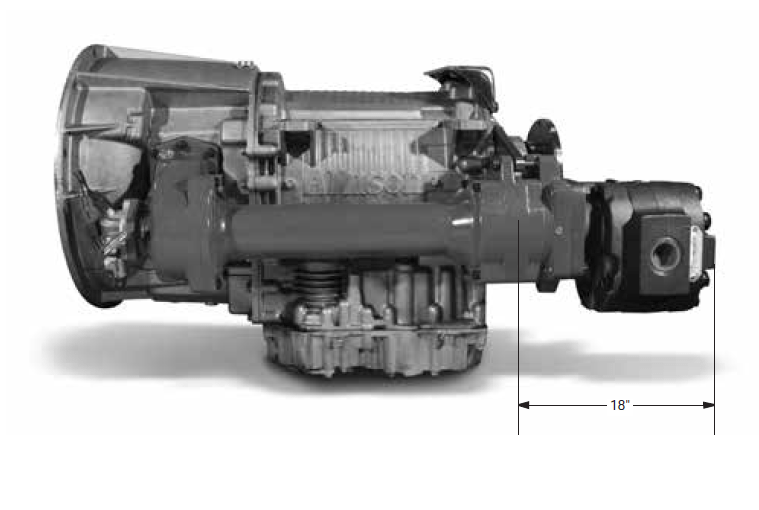

Chelsea recomienda encarecidamente u búukinta'al soportes utia'al u bombas (Soportes bix) ti' tuláakal le aplicaciones. Also remember to pack the female pilot of the PTO pump shaft with grease before installing the pump on the PTO.

Chelsea PTOs are designed and built to match a vehicle’s transmission, the gears of a PTO are of the same quality as the transmission’s gears. Le funcionamiento exitoso yaantal yo'osal le especificación yéetel u le instalación ti'alo'ob.